Fill-and-finish optimization — Improving efficiency

CONTACT USOptimizing the filling process in the pharmaceutical industry

The optimization of pharmaceutical drug fill-and-finish operations offers significant potential to reduce total costs. At SCHOTT Pharma, we promote a three-fold approach to improving line efficiency:

- Pinpointing high-risk areas of pressure and shock along the filling lines with SmartSkin.

- Identifying and understanding the root causes of container damage by vial analysis.

- Selecting the right drug container: EVERIC® strong & smooth vials for the ultimate filling line performance.

Identifying weak points in the filling process in the pharmaceutical industry

Whether it’s a major glass breakage event or failed quality inspection, identifying where exactly issues are occurring within the manufacturing process can be difficult and resource intensive. Misaligned guardrails; incorrect conveyor, buffer table, or starwheel settings; process transitions, and automated handling systems can all result in excess shocks and applied pressure.

These excess forces result in microfractures, surface damage, breakages, and pre-damage that increase the risk of a major event during production, failed quality inspections, and breakages during shipping and transportation.

Protect container integrity across the entire fill-and-finish process with SmartSkin

SmartSkin’s patented replica containers - also known as ‘drones’ - mimic the exact shape and size of standard and custom vials, syringes and cartridges. Equipped with hundreds of sensors, these drones are able to traverse filling and finishing lines during production or test runs to measure and map damaging forces.

Monitor surface pressure, horizontal and vertical shock, tilt, and rotation in real-time through washing, filling, capping, inspection and warehouse handling processes. Specialized drones also allow you to measure top load and sealing forces during capping and crimping processes, and residual seal force over time.

SmartSkin’s real-time force and motion data helps pharmaceutical manufacturers accelerate troubleshooting and investigations, optimize line setup and changeovers, and prevent unplanned downtime to improve yield and efficiency.

Unlock new potential in productivity and quality with SmartSkin Technologies. For more information, visit: Pharmaceuticals - SmartSkin

EVERIC® strong & smooth vials for the ultimate filling line performance

Strength testing and fractographic analysis

SCHOTT Pharma has decades of experience in strength testing and fractographic analysis. Axial, side, and burst pressure tests can be performed to analyze the influence of fill-and-finish process steps on container strength. In addition, fractographic analysis of broken containers can provide information on the origin of breakage, whether it’s the specific area of the container or contacts that potentially influenced the breakage. Based on these findings, the fill-and-finish line can be optimized and strength test analysis repeated to measure the effectiveness of any adjustments.

Find out moreGeometrically optimized vials for improved strength

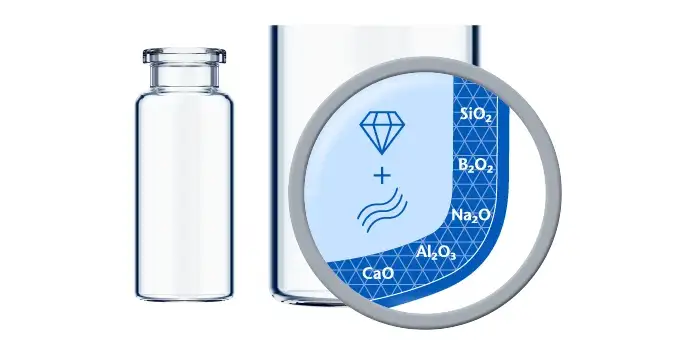

Even with a perfectly adjusted filling line, there is usually still room for further fill-and-finish optimization. EVERIC® strong is a geometrically optimized vial within ISO standards and unchanged borosilicate glass. Used in combination with a glass-to-glass contact-free manufacturing process, EVERIC® strong offers improved strength up to four times higher than the market standard. Statistical in-production release tests are performed to control the specified axial load (2,000 N) and side compression strength (1,000 N).

Find out moreEVERIC® strong and EVERIC® smooth offer the ideal combination

Used in combination with EVERIC® smooth low-friction outer coating, EVERIC® strong vials can fully realize their potential. With no sticking, climbing, or jamming, multiple tests have proven the superior performance of EVERIC® strong & smooth, with its surface-protective properties reducing cosmetic defects by up to 98 %. This results in line speeds potentially increased by more than 100 % compared to standard lines. With EVERIC® strong & smooth the risk of breakage can be reduced and line performance ultimately optimized.

Find out more