EVERIC® vials

A modular vial concept for rising drug requirements

Modern medicine is essential to health and life. Through constant research and development, drugs have become more and more personalized, with their complex structures demanding increasingly special requirements. We help to keep them reliable, safe, and effective as they reach people to maintain or improve their health.

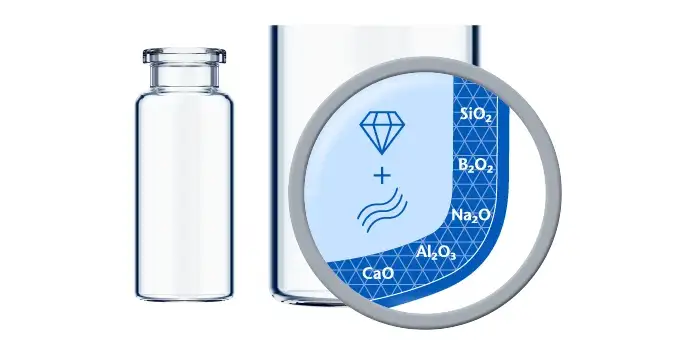

SCHOTT Pharma's EVERIC® vials present an innovative modular container concept for the pharmaceutical industry, seamlessly connecting manufacturers and users through a range of integrated benefits. Each module is crafted from FIOLAX® Type I Borosilicate Glass, renowned for its exceptional properties.

Different needs require flexible solutions

Pharmaceutical companies face significant challenges in choosing the appropriate vial for their medicines as they become more complex and have more specific requirements. The vial’s inner surface is crucial for keeping drug-container interaction to a minimum and maintaining the medication’s efficacy. Features such as precise geometry and an improved outer surface can further optimize the fill-and-finish process.

Sensitive injectables such as biologics

Conventional vials can encounter increased leachable levels caused by a change in the inner surface of the near-bottom region of the vial during hot-forming. This is particularly relevant for low-filled vials, which are used to store high-value biologics. Glass leachables can cause stability issues for complex and sensitive molecules, leading to pH-shift, protein aggregation, or denaturation. This is even more challenging for drugs buffered in high pH solutions. In addition, conventional vials have a higher risk of glass delamination, which can pose a huge threat to patient safety. The vial’s inner surface can also influence the adsorption of proteins, which can cause issues for drug concentration.

Deep-cold therapies

The rise of mRNA vaccines introduced new therapies that need to be stored at deep-cold temperatures. Combined with the potential of multiple freeze-thaw cycles, the stress on the glass can increases the chances of vial breakage, especially if the containers are pre-flawed. The risk of breakage is of paramount concern to pharmaceutical companies given the significant value of the drugs.

Fill-and-finish processing

During conventional bulk fill-and-finish processing, vials are constantly subjected to glass-to-glass contact and load. This can result in an increase in cosmetic defects, a higher risk of breakage, and the potential for sticking and climbing during depyrogenation. The consequences of this are reduced line speed, higher final rejects, and increased downtimes and interruptions, resulting in elevated costs.

Unique traceability

Traceability for individual containers has a huge potential that’s yet to be exploited by the pharmaceutical industry. Targeted recalls, a reduced risk of mix-ups, optimization during fill-and-finish, and optimization of freeze-drying processes are just a few areas where a unique code can help to reduce costs and increase safety.

There is no “unsolvable” with EVERIC® vials

Consisting of six modules, SCHOTT Pharma EVERIC® vials provide a solution for each of these challenges:

- EVERIC® pure and EVERIC® care offer dedicated inner surfaces to minimize drug-container interaction.

- EVERIC® strong and EVERIC® freeze feature optimized geometries and handling to maximize vial strength for a dedicated application.

- EVERIC® smooth has a coating on its outer surface to increase line speed and reduce cosmetic defects during fill-and-finish.

- EVERIC® smart enables traceability throughout the complete supply chain via a unique identification.

Create the vial tailored to your individual challenges

It’s not uncommon to face multiple challenges when selecting the appropriate vial. During the drug development stage, the primary focus is on drug stability, with a particular emphasis on the vial's inner surface. However, in later stages, the container's stability and strength become a crucial factor to consider. Looking further ahead, manufacturing aspects become critical, including achievable line speed and reject rates during fill-and-finish. EVERIC® was specifically designed to address these challenges, and the properties of various EVERIC® vials can be combined to solve multiple issues simultaneously.

Discover the EVERIC® modularity in the visualization below.

EVERIC® vials – your holistic solution

SCHOTT Pharma’s EVERIC® vials provide tailor-made solutions for all requirements so that medication can securely be stored, transported, and administered to fully benefit the patient. EVERIC® vials deliver medical progress to people, and our goal is to always provide the best possible individual care. Advantages at a glance: