Mechanical stability testing of pharmaceutical products Characterize pharmaceutical container strength and understand the origins of breakage

contact usAssure product reliability and guide line optimization

Characterizing the mechanical stability of pharmaceutical products is important for two major cases: product specification and process optimization.

For pressure-sensitive products such as containment solutions for emergency pens, the specification and verification of mechanical strength is vital, since it ensures reliability at the moment of use. For process optimization, mechanical strength testing and fractographic analysis methods guide root-cause investigations into glass breakage and verify the appropriate optimization measures.

Mechanical strength testing: Reading systematic change

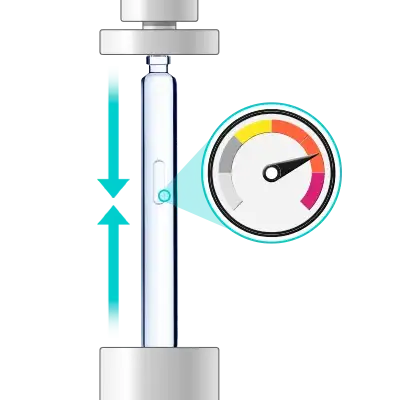

In the mechanical stability testing of pharmaceutical products, containers are loaded with controlled and increasing pressure until breakage occurs. When testing a larger set of containers with the same production and process history, the resulting statistics give a breakage probability.

To investigate the origins of glass breakage on production lines such as fill and finish, sample sets are taken at different positions along the process chain. If a physical impact occurs at a specific stage in the production or filling process, a clear change in the breakage probability curve will be visible for the sample sets representing the status before and after this production stage. The results may also reveal a change in position on the container where the cracks appear. This is another indicator of a changing breakage mechanism.

These observations provide evidence for the systematic impact of line processes or production modules on mechanical stability and the extent of a reduction in strength. Customers can use the resulting data to draw conclusions and decide whether the investigated line module impacts mechanical stability or not. This way customers ensure to invest time and money for line optimization only where it's relevant. After optimization measures, the repetition of the mechanical strength testing creates evidence to assess the achieved improvement effect.

Fractography: Reading the origins of breakage events

Container breakage is a critical event, particularly during filling, so an investigation of its origins led by the quality department is essential. However, all that is usually left is a broken container and a few shards.

This is where fractographic analysis comes in. By characterizing the fracture patterns of cracked or broken containers, experts can read the indications of the breakage process, the contact materials responsible, and the forces involved. Our fractography experts can support your investigations by revealing the origins of breakage events that cannot be read by non-specialists.

Learn about the nature of glass, its proper handling, and reasons for breakage

Mechanical stability testing: How to proceed

SCHOTT Pharma Services’ team of specialists offers support and advice about your pharmaceutical packaging challenge. We provide guidance and a complete process that will take you from initial request to effective solution.