Climate action

Scientifically proven, climate change is a highly critical risk for life on earth. At SCHOTT Pharma, we have committed to take responsibility for the impacts of our business operations. Described in the United Nations Sustainability Development Goal 13 as “Take urgent action to combat climate change and its impacts”, climate action is one of the four strategic pillars of the entire SCHOTT Group.

In 2020 the entire SCHOTT group began its decarbonization program. Utilizing the synergies across all business units, the program drives decarbonization as a Group-wide priority. In particular, the program reduces emissions by:

- Improving energy efficiency,

- Using green electricity across all sites (operational since 2021)

- And initiating technology change.

With an initial focus on reduction of Scope 1 and Scope 2 GHG emissions, we completed our climate actions in 2023 by extension to Scope 3 and external validation of our roadmap and targets.

Commitment to science-based targets

As a research-focused company, we are driven by scientific evidence, so we joined the independent Science Based Targets initiative (SBTi). In 2023, SCHOTT Group's climate action roadmap and targets were validated by the SBTi. This intensive review confirmed that our roadmap is in line with the current state of climate science and supports the requirements of the Paris Agreement to limit global warming to 1.5 °C. The validated targets include a commitment to:

- Reducing our absolute Scopes 1 and 2 GHG emissions by 46.2% by fiscal year 2030.

- Reducing our absolute Scope 3 GHG emissions from fuel and energy-related activities (Scope 3.3) as well as investments (3.15) by 27.5% by fiscal year 2030

- Engaging our supply chains to cover 74.23% of the Scope 3 emissions related to purchased goods and services (Scope 3.1), capital goods (Scope 3.2) and upstream transportation and distribution (Scope 3.4) using suppliers with their own scientific reduction targets by 2027.

Set and validated for the Group, SCHOTT Pharma is equally committed to meeting those targets for the scope of business. SCHOTT Pharma will therefore transparently report its actions and progress towards those targets in its non-financial reporting, starting with the report for fiscal year 2024.

From understanding the drivers to specific action

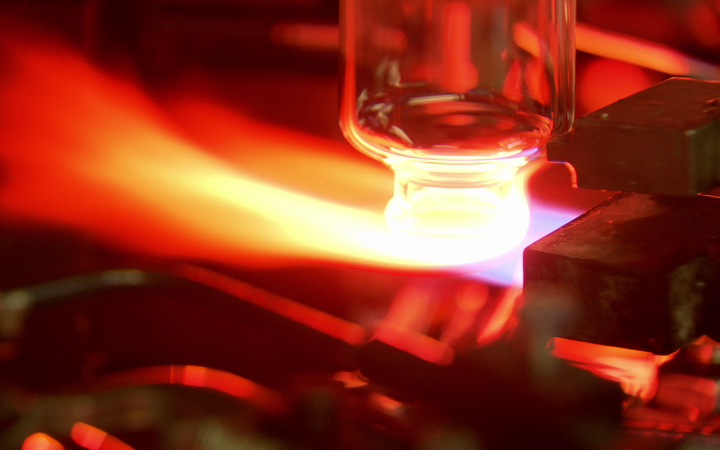

The state-of-the art manufacture of glass-based drug containment solutions requires fossil fuel to melt borosilicate glass tubes as well as for conversion of the glass tubes into final geometry of syringes, cartridges, vials or ampoules. This use of fossil fuel in production is the largest driver of GHG emissions, followed by the electric operations for automated processes, facility and cleanroom management and other energy consumption for crossover technologies. Additionally, externally sourced goods and services such as packaging materials and capital goods increase the Scope 3 footprint of our operations.

To reduce SCHOTT Pharma’s GHG emissions, specific actions are taken in the following areas: