Circular packaging without compromising patient safety: SCHOTT Pharma, Corplex, and Takeda successfully demonstrated closed-loop recycling

Tuesday, October 8, 2024, Mainz, Germany

- Together with Takeda and Corplex, SCHOTT Pharma successfully completed a ton-scale pilot study to increase resource efficiency and reduce carbon emissions in the pharmaceutical supply chain.

- The large-scale study demonstrated the technical and supply chain feasibility of closing the loop for trays used to package and transport pharma drug containment solutions, allowing to reduce greenhouse gas (GHG) emissions by up to 50% per tray while applying 70% recycled content.

SCHOTT Pharma, a pioneer in drug containment and delivery solutions, Corplex, an expert in design, manufacturing, and recycling of transport packaging, along with Takeda, a leading pharmaceutical company, are collaborating to advance circular economy solutions in the pharmaceutical industry. Together, the companies have initiated a pilot study on closed-loop recycling of single-use trays. These are used to hold vials, cartridges, and ampoules during transport and are currently disposed after a single use. “We want to set new standards with our collaboration and ultimately help to reduce the environmental impact of the pharma industry. By developing a system for closed-loop recycling of trays, we are working towards a solution that increases material efficiency and reduces carbon emissions without compromising quality or patient safety,” said Andreas Reisse, CEO of SCHOTT Pharma. The ton-scale study demonstrated the way trash containers filled with single use plastic packaging can transform into future material sources. A peer-reviewed life cycle assessment confirmed the reduced environmental impact of closed-loop recycling: material can be recirculated after use, applied at the same quality level, and cuts GHG emissions per tray by up to 50% while applying 70% recycled content compared to using virgin single-use trays. The closed-loop system allows recirculation of valuable polypropylene at the same quality level.

The pharma industry is a highly regulated market as life-saving medications must reach the patients safely. Today’s approach to avoid contamination is the application of single-use components and the use of virgin raw materials. This is also the case for intermediary packaging, such as trays that protect the pharma drug containers during storage and transport to ensure safe and reliable use thereafter. These single-use tray solutions are made of high-quality polypropylene that are usually disposed or downcycled once the containers have been shipped to the pharma company. While this focus on high quality requirements is a standard procedure, it is in tension with the important aspect of resource responsibility framed in UN Sustainable Development Goal 12. In a pilot project, SCHOTT Pharma, Corplex, and Takeda have investigated the question of how both requirements can be combined and how they can be implemented in practice.

“For nearly 50 years, we have helped industrial companies integrate recycled material into their production cycles. So far, use of recycled material has remained an exception in the pharma industry. We are excited about the jointly established solution paving the way for recycled material in pharma packaging,” said Lucas van der Schalk, CEO of Corplex.

Together, the three partner companies carried out an elaborate large-scale pilot. The focus was on optimizing operational efficiency in reverse logistics, verifying technical feasibility in reprocessing, and assessing environmental impact. In 13 collections, around 20 tons of used packaging material were returned in a clean and controlled manner from production environments at Takeda and SCHOTT Pharma to Corplex. The collected material was reprocessed into granulate, and new trays were manufactured. The pilot was accompanied by an extensive lab study to investigate granulate and tray quality over multiple recycling cycles. The lab results showed that trays from closed-loop recycled material equally fulfill the requirements for their application compared to trays manufactured from virgin material.

A peer-reviewed life cycle assessment, performed by the LCA Centre, confirmed significant environmental advantages of trays from the closed-loop recycling system over trays from virgin materials. The life cycle assessment was prepared in accordance with relevant ISO norms and the acknowledged standards of the IPCC (Intergovernmental Panel on Climate Change) Global Warming Potential (GWP 100a). The assessment identified reduced GHG emissions of up to 50% for trays with 70% recycled content.

Next steps: Scaling from pilot to routine operations and supporting overall industry transformation

“Our top priority is to minimize the environmental impact of our products and services based on the principles of a circular economy. The successful pilot study has shown us that we are on the right track. The next step is to bring the pilot into routine operations with our partners at SCHOTT Pharma and Corplex,” said Johanna Jobin, Global Head of Environment and Sustainability at Takeda.

This joint pilot successfully proved that closed-loop recycling can increase resource efficiency and reduce emission in a ton-scale demonstration. As next step, the closed-loop recycling system will undergo scaling and success factors like the standardization of tray dimensions are reviewed. In sum, enabling the inclusion of other pharmaceutical companies and, as such, supporting the industry's transformation towards more sustainable practices.

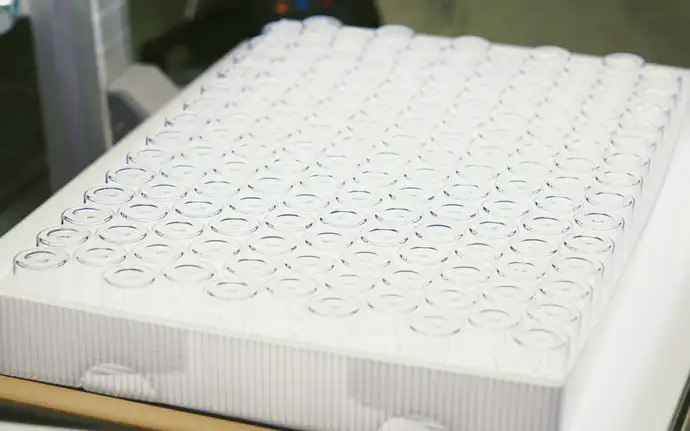

For safety reasons, packaging in the pharmaceutical industry is usually single use. Together with Takeda, and Corplex, SCHOTT Pharma is now closing the loop to recycling for the first time. Image: SCHOTT Pharma

Polypropylene is extracted from the used trays, which in turn can be used to produce new trays to package and transport pharmaceutical vials or cartridges. Image: SCHOTT Pharma

About SCHOTT Pharma

Human health matters. That is why SCHOTT Pharma designs solutions grounded in science to ensure that medications are safe and easy to use for people around the world. The portfolio comprises drug containment solutions and delivery systems for injectable drugs ranging from prefillable glass and polymer syringes to cartridges, vials, and ampoules. Every day, a team of over 4,600 people from over 60 nations works at SCHOTT Pharma to contribute to global healthcare. The company is represented in all main pharmaceutical hubs with 16 manufacturing sites in Europe, North and South America, and Asia. With over 1,000 patents and technologies developed in-house and a state-of-the-art R&D center in Switzerland, the company is focused on developing innovations for the future. SCHOTT Pharma AG & Co. KGaA is headquartered in Mainz, Germany and listed on the Frankfurt Stock Exchange as part of the MDAX. It is part of SCHOTT AG, which is owned by the Carl Zeiss Foundation. In light of this spirit, SCHOTT Pharma is committed to sustainable development for society and the environment and has the strategic goal of becoming climate-neutral by 2030. Currently, SCHOTT Pharma has over 1,800 customers including the top 30 leading pharma manufacturers for injectable drugs and generated revenue of EUR 899 million in the fiscal year 2023. Further information at www.schott-pharma.com

Lea Kaiser

PR & Communications Manager

Research Gate

Research Gate