Designing a pathway towards net-zero injection devices

Climate change awareness has reached an apparent tipping point. Industry leaders worldwide are beginning to take credible actions in transitioning to net-zero or circular economies – but a change of this magnitude cannot happen in a vacuum. At SCHOTT Pharma, we believe such change requires solid cross-industry collaboration.

We are dealing with critical devices which, nevertheless, have limited service longevity and little reusability. So, how can we gain more out of the applied resources without impairing patient safety and convenience? How can we reduce the related carbon emission in the pharmaceutical value chain?

Introducing Alliance to Zero

At SCHOTT Pharma, we are keenly aware of the challenges inherent in achieving net-zero emissions objectives. Driving down emissions requires strong collaboration across the industry and thinking from an ecosystem perspective. The Alliance to Zero is an organisation co-founded in 2021 by SCHOTT Pharma and seven other pharmaceutical supply companies, whose goal is to facilitate the transition of the pharma sector to compliance with net zero emissions. The aim is to collaboratively find ways to decarbonize the value chain for injection devices.As an industry alliance, the goal is to develop alternative concepts on product, business model and ecosystem level, which support pharma companies to realize true net-zero pharma products by 2030. The roadmap to net-zero starts now, with understanding the current environmental and carbon footprint of such products. Through e.g. conference presentations and a joint industry workshop with the Parenteral Drug Association, the Alliance to Zero raises the awareness in the industry on what drives critical greenhouse gas emissions in pharma supply chains. Over the next few years, the Alliance to Zero believes, it is essential to transparently design tangible and effective solutions for a successful net-zero product offering. These relatively simple steps can be a powerful springboard to realising significant GHG emission reductions across the pharmaceutical industry. But how do we achieve this?

Cross-industry life cycle assessments

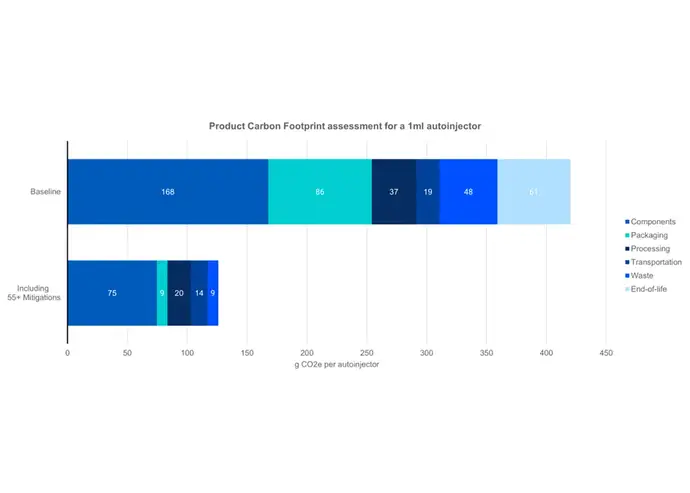

To analyze the status quo and identify the key drivers for carbon emissions related to injection devices, the Alliance to Zero collectively prepared a cross-company life cycle assessment (LCA). The 1ml autoinjector was chosen as a pilot product to evaluate emission contributions along the value chain - from raw materials and manufacturing to distribution, use, and end-of-life. As it covers the entire life cycle, this approach is called a cradle-to-grave assessment. To ensure the creation of representative data, the Alliance to Zero created its own guideline for the application of the existing methodological LCA descriptions to the specific case of injection devices and consolidation of cross-company input.Overall, we determined the example device to have a product carbon footprint that is equivalent to roughly 774g of CO2. Key driver with more than 50% of the footprint lies in the applied raw materials and their single-use before they face their end-of-life. This is why the Alliance to Zero believes a transformation into a circular economy approach is essential to reach net zero. This way, the end-of-life of the material becomes the birth of life, meaning: instead of creating carbon emissions at the end-of-life, recollected materials or even sub-assembled components could replace a high share of the raw materials. Besides carbon emissions, such circular scenarios would further reduce waste volumes and dependency on fossil resources.

Forecasted PCF after successful implementation of 55+ mitigation options for the example f a 1ml autoinjector (reproduced by permission from Alliance to Zero)

What are your ideas on zero-carbon drug delivery?

How would you promote sustainability in pharmaceutical packaging and transform our industry for a net-zero future? Contact a member of the SCHOTT Pharma sustainability team today. We are open to collaboration and look forward to making an impact with you.

Dr. Arne Kloke

Head of Service and Sustainability Management

Register for the latest news

Stay up to date with information about SCHOTT Pharma products and services by registering for our newsletter.